Steps of Horizontal Drilling: A Comprehensive Guide

Horizontal drilling is a revolutionary technique used in the oil and gas industry to access hard-to-reach reserves and enhance production efficiency. This process involves drilling wells at an angle from the vertical, allowing for the extraction of resources from multiple layers of rock. In this article, we’ll delve into the key steps of horizontal drilling.

1. Well Planning and Site Preparation

Prior to beginning horizontal drilling, thorough planning and site preparation are crucial. Geologists and engineers assess the geological formations to determine the best location for the well. Factors like rock composition, pressure, and temperature are taken into account. Once the drilling site is chosen, equipment and machinery are transported to the location.

2. Vertical Drilling

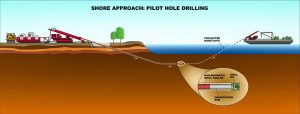

The first step in horizontal drilling is vertical drilling, similar to traditional drilling techniques. A vertical wellbore is drilled into the ground until it reaches the target rock formation. This vertical portion of the well will serve as the starting point for the horizontal section.

3. Kickoff Point

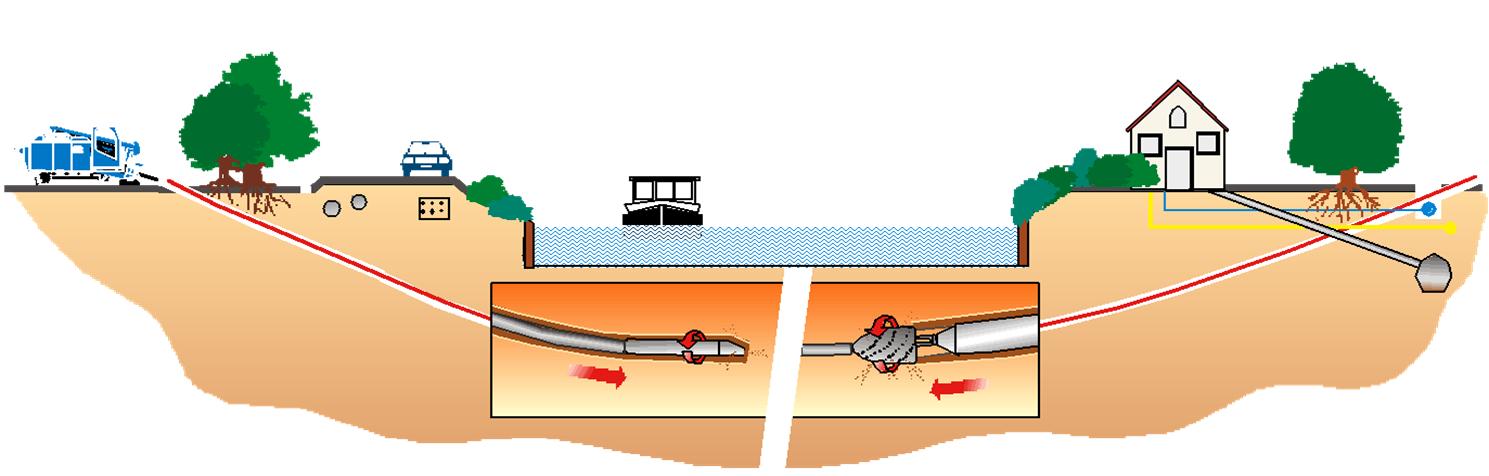

After the vertical wellbore is drilled, the next step is to create a “kickoff point.” This involves using specialized tools to deviate the wellbore from vertical to the desired horizontal angle. The kickoff point is where the horizontal drilling will commence.

4. Drilling the Horizontal Section

With the kickoff point established, the drilling process continues horizontally through the target formation. Advanced drilling tools, including rotary steerable systems and mud motors, are used to control the direction and trajectory of the wellbore. These tools enable precise navigation through the rock layers.

5. Steering and Navigation

During the drilling of the horizontal section, real-time data is collected and analyzed to ensure accurate navigation. Measurement While Drilling (MWD) and Logging While Drilling (LWD) technologies provide information about the well’s position, inclination, and formation characteristics. This data allows drillers to make necessary adjustments to maintain the desired path.

6. Casing and Cementing

Once the horizontal section is drilled, casing is installed to reinforce the wellbore’s structure and prevent collapses. Cement is then pumped into the annular space between the casing and the formation, creating a secure seal. Proper casing and cementing are vital to prevent fluid migration between different rock layers. https://drillitco.com.au/

7. Completion and Production

After the well is drilled, cased, and cemented, completion operations begin. This involves perforating the casing in specific intervals to allow hydrocarbons to flow into the wellbore. Hydraulic fracturing (fracking) may also be conducted to enhance production by creating fractures in the rock. Production tubing and other equipment are installed to extract the resources to the surface.

8. Monitoring and Maintenance

Once the well is in production, ongoing monitoring and maintenance are essential. Engineers and technicians closely monitor well performance, production rates, and the condition of equipment. Regular maintenance ensures the longevity and efficiency of the horizontal well over time.

Conclusion

Horizontal drilling has revolutionized the oil and gas industry, allowing for increased access to valuable resources and improved production rates. The step-by-step process of horizontal drilling involves careful planning, precise navigation, and proper well completion. By following these steps, engineers can successfully tap into hard-to-reach reserves and contribute to the energy landscape.