How Does Rock Drilling Work?

Rock drilling is a crucial process in various industries, from construction to mining. It involves creating holes or cavities in solid rock formations to access valuable resources or facilitate construction projects. In this comprehensive guide, we will delve into the inner workings of rock drilling, exploring the methods, tools, and technology that make it all possible.

Understanding the Basics of Rock Drilling

Rock drilling is not a one-size-fits-all process; rather, it encompasses several techniques depending on the specific geological conditions and the purpose of the drilling. Here are some fundamental aspects to consider:

1. Geological Assessment

Before drilling begins, geologists assess the rock formation to determine its composition, hardness, and other critical characteristics. This information helps in selecting the appropriate drilling method and equipment.

2. Drilling Methods

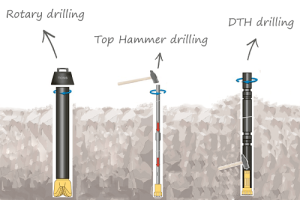

There are several methods for rock drilling, including:

- Rotary Drilling: This method uses a rotating drill bit to crush and penetrate the rock. It is commonly used in mining and oil drilling.

- Percussion Drilling: In this method, a hammering action is applied to the drill bit to break the rock into small fragments.

- Directional Drilling: This technique allows for drilling at specific angles or curves, making it ideal for applications such as drilling for oil wells or underground utilities.

Tools and Equipment

The tools and equipment used in rock drilling are precision-engineered to withstand the extreme forces and conditions encountered during the process. Key components include:

1. Drill Bits

Drill bits come in various shapes and sizes, each designed for specific rock types. Tungsten carbide or diamond bits are often used for their durability and cutting efficiency.

2. Drill Rigs

Drill rigs provide the necessary power and stability for the drilling operation. They range from small, portable units for construction to massive rigs for deep mining.

3. Drill Fluids

Drill fluids, such as mud or water, are used to cool the drill bit, remove rock cuttings, and provide lubrication. This ensures smooth and efficient drilling.

The Role of Technology

Advancements in technology have revolutionized rock drilling. Modern drilling operations often incorporate:

1. Automation

Automated drilling systems can optimize drilling parameters, reducing human error and improving efficiency. These systems also allow for remote operation, enhancing safety in hazardous environments.

2. Geophysical Imaging

Geophysical imaging techniques, such as seismic surveys and ground-penetrating radar, help identify the best drilling locations by mapping subsurface rock structures. https://drillitco.com.au/drill-it-group-australia/

3. Environmental Considerations

Efforts are made to minimize the environmental impact of rock drilling. This includes proper waste disposal and the use of eco-friendly drilling fluids.

Conclusion

Rock drilling is a complex and essential process that underpins various industries. From the geological assessment of rock formations to the selection of drilling methods and the use of advanced technology, this guide has provided insights into how rock drilling works. As technology continues to advance, we can expect further improvements in efficiency, safety, and sustainability in the world of rock drilling.