Exploring the Importance of Hole Spacing in Blasting Operations

When it comes to blasting operations, safety, precision, and efficiency are paramount. Achieving these goals requires careful consideration of various factors, and one of the critical elements is hole spacing. In this comprehensive guide, we’ll delve into the significance of hole spacing in blasting, its impact on safety and effectiveness, and how to optimize it for your specific needs.

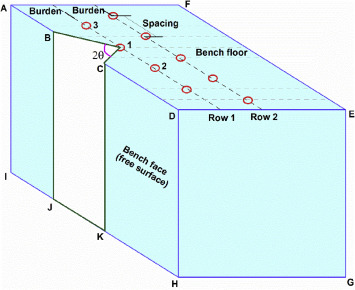

The Basics of Hole Spacing

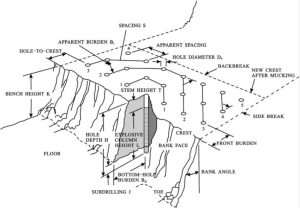

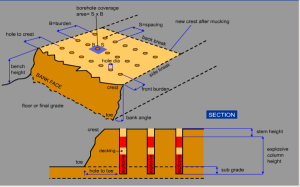

Hole spacing, as the name suggests, refers to the distance between blast holes drilled into the rock or other materials to be blasted. Proper hole spacing is essential for ensuring a controlled and effective blast that minimizes risks and maximizes results. The ideal hole spacing can vary based on several factors, including the type of material, the desired fragmentation, and safety considerations. For drill it group blast hole drilling see this.

Factors Influencing Hole Spacing

Several key factors come into play when determining the appropriate hole spacing for a blasting operation:

- Rock Type: Different types of rock have varying densities and properties, which can influence the required hole spacing. Harder rocks may require closer spacing to break effectively, while softer rocks may require wider spacing for optimal results.

- Blast Design: The design of the blast pattern, including the number and arrangement of blast holes, plays a crucial role in determining the hole spacing. Well-planned blast designs help achieve the desired fragmentation and avoid overblasting or underblasting.

- Explosives Used: The type and quantity of explosives used affect the energy released during the blast. This, in turn, impacts the hole spacing required for effective fragmentation and material displacement.

- Safety: Safety is a primary concern in any blasting operation. Maintaining safe distances between blast holes is crucial to prevent accidents and ensure the well-being of the personnel involved in the operation.

Optimizing Hole Spacing for Blasting

Efficient and effective hole spacing is essential for a successful blasting operation. Here are some key steps to optimize hole spacing:

1. Site Assessment

Begin by conducting a thorough assessment of the site. Understand the geology, rock properties, and any potential hazards that could affect the blasting process. This information will help you determine the appropriate hole spacing for your specific site.

2. Blast Design

Collaborate with blasting engineers to create a detailed blast design. Consider the type and quantity of explosives, the desired fragmentation, and the overall blast pattern. The blast design will guide you in determining the ideal hole spacing for your project.

3. Safety Precautions

Always prioritize safety. Ensure that the chosen hole spacing adheres to safety regulations and allows for safe distances between blast holes. Implement safety measures such as warning signals, evacuation plans, and protective equipment for personnel on-site.

4. Monitoring and Adjustments

During the blasting operation, closely monitor the results. If the desired fragmentation is not achieved, or if there are safety concerns, be prepared to make adjustments to the hole spacing as necessary. Flexibility is key to a successful blasting operation.

The Impact of Hole Spacing on Blasting

The significance of hole spacing cannot be overstated. Properly spaced blast holes contribute to the following crucial aspects of blasting operations:

1. Fragmentation

Optimal hole spacing is essential for achieving the desired fragmentation of the material being blasted. Too close spacing can lead to overblasting, while too wide spacing may result in underblasting. The right balance is key to efficient material breakage.

2. Vibration and Airblast Control

Controlling ground vibrations and airblasts is vital to prevent damage to nearby structures and ensure community safety. Appropriate hole spacing helps mitigate these effects, reducing the environmental impact of blasting.

3. Material Displacement

The spacing between blast holes influences the direction and degree of material displacement. This factor is particularly important in mining and construction projects where precise material movement is critical for success.

4. Cost Efficiency

Efficient hole spacing leads to cost savings in terms of explosives used and labor required. By optimizing the spacing, you can reduce the overall expenses associated with blasting operations.

Conclusion

In the world of blasting, hole spacing is a critical element that affects safety, efficiency, and effectiveness. By understanding the factors influencing hole spacing and following a strategic approach to optimization, blasting operations can achieve their goals while minimizing risks. Prioritizing safety, conducting site assessments, and collaborating with experienced blasting engineers are all essential steps in ensuring that your blasting project is a success.

Remember, hole spacing is not a one-size-fits-all solution; it needs to be tailored to the specific requirements of your project. By doing so, you’ll be on the path to a successful and well-executed blasting operation.