How Accurate is Directional Drilling Methods?

The Advancements in Directional Drilling Technology

Directional drilling is a crucial technique in the oil and gas industry, allowing companies to access reserves that would otherwise be difficult or impossible to reach using conventional drilling methods. But just how accurate is directional drilling, and what advancements have been made to improve its precision? In this article, we will delve into the world of directional drilling, explore its accuracy, and discuss the technologies that have revolutionized this vital process. How accurate is directional drilling methods?

Understanding Directional Drilling

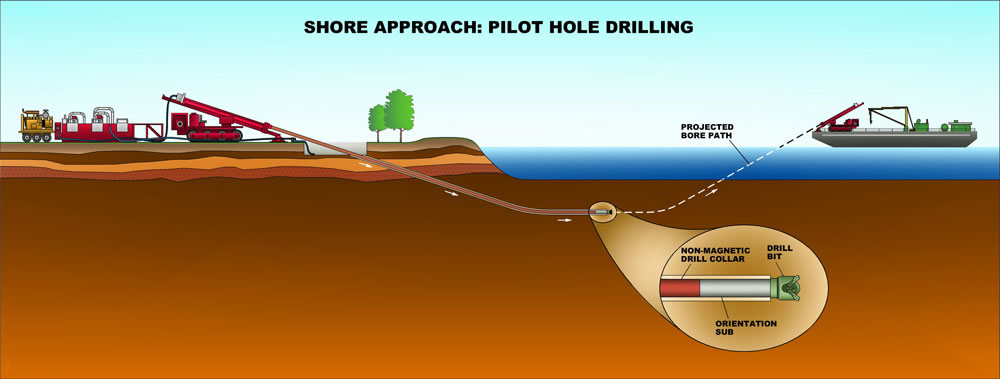

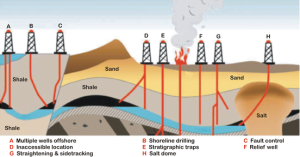

Directional drilling, also known as slant drilling or deviated drilling, is a method used to control the trajectory of a borehole, enabling it to follow a specific path beneath the Earth’s surface. This technique has numerous applications, from reaching oil and gas deposits located beneath urban areas, bodies of water, or sensitive environmental areas to creating underground utility tunnels and even geothermal energy extraction.

The accuracy of directional drilling is critical in various industries, as even minor deviations from the planned path can lead to costly delays, environmental damage, or the failure to reach valuable resources. To assess the accuracy of directional drilling, we must consider both the historical methods and the recent technological innovations that have enhanced its precision.

The Historical Perspective

In the early days of directional drilling, accuracy was limited. Drillers had to rely on their experience, instincts, and basic tools to navigate underground. This often resulted in a significant margin of error, which could lead to costly consequences.

The Role of Gyroscopic Tools

One significant improvement in directional drilling accuracy was the development and adoption of gyroscopic tools. These tools use the Earth’s gravitational pull to determine the wellbore’s orientation accurately. By understanding the borehole’s direction in real-time, drillers can make necessary adjustments to ensure they stay on course. However, even with gyroscopic tools, there remained room for improvement.

Modern Advancements in Directional Drilling

The 21st century has witnessed remarkable advancements in directional drilling technology, greatly improving accuracy and efficiency.

1. Measurement While Drilling (MWD)

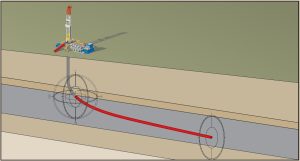

One of the game-changing technologies in directional drilling is MWD. MWD systems allow real-time data transmission from downhole tools to the surface. These tools collect critical information about the wellbore’s trajectory, including its inclination and azimuth. With this data, drillers can make rapid, precise adjustments, ensuring that the borehole follows the desired path with unprecedented accuracy.

2. Logging While Drilling (LWD)

LWD is another revolutionary technology that has enhanced directional drilling accuracy. LWD tools provide real-time information about the geological formations encountered during drilling. By analyzing this data, drillers can make informed decisions to avoid obstacles and maintain the borehole’s intended path. LWD systems have become invaluable in navigating complex subsurface environments.

3. Advanced Drilling Software

Accurate directional drilling also relies on sophisticated software programs that incorporate data from MWD, LWD, and other sources. These programs allow drillers to visualize the wellbore’s progress, plan ahead, and make real-time adjustments. The combination of advanced hardware and software has transformed directional drilling into a highly precise and predictable process.

The Benefits of Enhanced Accuracy

The improved accuracy of directional drilling methods has numerous benefits for various industries: For drill it group slant drilling see here.

1. Cost Savings

Enhanced accuracy reduces the likelihood of costly errors, such as drilling into the wrong formation or encountering unexpected obstacles. This, in turn, lowers drilling expenses and minimizes downtime.

2. Environmental Protection

Accurate directional drilling helps protect the environment by reducing the risk of oil or gas leaks, groundwater contamination, and damage to sensitive ecosystems. It allows drillers to navigate around environmentally sensitive areas with greater confidence.

3. Resource Maximization

Precise directional drilling ensures that companies can access the maximum amount of valuable resources from a single well. This maximization of resource extraction is vital for the economic viability of drilling operations.

Conclusion

Directional drilling has come a long way from its early days of trial and error. Advancements in technology, including MWD, LWD, and advanced software, have made directional drilling incredibly accurate. This precision has not only reduced costs and minimized environmental impact but has also unlocked previously inaccessible reserves of oil, gas, and other resources. As technology continues to evolve, the accuracy of directional drilling methods is expected to improve even further, ensuring a sustainable and efficient future for the oil and gas industry.

In summary, the answer to the question “How accurate is directional drilling?” is that it has become exceptionally accurate, thanks to modern innovations that have revolutionized the industry.