The Art of Precision: Understanding Directional Drilling Techniques

In the realm of modern engineering, precision is paramount. Nowhere is this more evident than in directional drilling techniques, where the ability to navigate underground with accuracy can make all the difference in project success. From oil and gas exploration to infrastructure development, directional drilling has revolutionized how we access resources and build critical infrastructure. In this comprehensive guide, we delve into the intricacies of directional drilling, exploring its techniques, applications, and importance. The Art of Precision: Understanding Directional Drilling Techniques

The Basics of Directional Drilling

Directional drilling is a method used to control the trajectory of a drill bit to reach specific subsurface targets. Unlike vertical drilling, which goes straight down, directional drilling allows engineers to drill at various angles, including horizontally. This capability opens up a world of possibilities, enabling access to reserves that were previously inaccessible or too costly to reach.

Tools of the Trade

To achieve precision in directional drilling, engineers rely on an array of sophisticated tools and technologies. One such tool is the measurement while drilling (MWD) system, which provides real-time data on the drill’s position, direction, and inclination. This information allows operators to make immediate adjustments, ensuring the drill stays on course.

Techniques for Precision

Several techniques are employed to ensure precision in directional drilling. One common method is rotary steerable drilling, where the drill bit is steered using downhole motors controlled by surface computers. This approach offers greater control and accuracy compared to traditional methods, resulting in smoother wellbores and increased productivity.

Applications of Directional Drilling

The versatility of directional drilling makes it indispensable across various industries. In the oil and gas sector, directional drilling is used to access reservoirs located beneath sensitive environments or urban areas. By drilling horizontally, operators can minimize surface disturbance while maximizing resource recovery.

Environmental Benefits

Directional drilling also offers significant environmental benefits. By reducing the need for extensive surface infrastructure and minimizing land disturbance, it helps preserve natural habitats and ecosystems. Additionally, directional drilling can mitigate the risk of accidents such as oil spills, safeguarding the environment for future generations.

Infrastructure Development

In addition to energy exploration, directional drilling plays a crucial role in infrastructure development. It allows for the installation of underground utilities, such as pipelines and fiber-optic cables, with minimal disruption to existing structures and landscapes. This is particularly advantageous in urban areas where space is limited and surface disturbances are highly undesirable.

The Importance of Precision

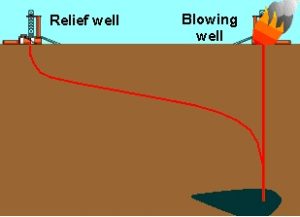

Precision is not merely a goal in directional drilling; it is a necessity. The consequences of deviation from the intended path can be severe, ranging from increased project costs to environmental damage and safety hazards. By prioritizing precision, engineers can mitigate these risks and ensure the successful completion of drilling projects.

Safety Considerations

Safety is paramount in directional drilling operations. Deviations from the planned trajectory can result in collisions with existing wells or underground infrastructure, posing serious safety risks. By adhering to strict safety protocols and utilizing advanced monitoring technologies, operators can minimize these risks and protect both personnel and assets.

Economic Benefits

Precision drilling also yields significant economic benefits. By optimizing well placement and maximizing resource recovery, operators can enhance production rates and profitability. Additionally, the ability to access previously inaccessible reserves opens up new revenue streams, driving economic growth and energy security.

Conclusion

In conclusion, directional drilling is a cornerstone of modern engineering, enabling precise navigation of underground environments for various applications. By harnessing advanced technologies and techniques, engineers can achieve unparalleled levels of precision, ensuring the success of drilling projects while minimizing environmental impact and maximizing economic returns. As we continue to push the boundaries of exploration and development, the art of precision in directional drilling will remain indispensable.