The Science Behind Underground Drilling: Exploring Subterranean Frontiers

The Evolution of Underground Drilling

In the annals of human history, the quest for resources has often led us beneath the Earth’s surface. From ancient mining shafts to modern-day tunnels, the science behind underground drilling has evolved significantly. Early civilizations relied on primitive tools and sheer human effort to access subterranean riches. However, advancements in engineering, geology, and technology have revolutionized the way we explore and extract resources from beneath the ground.

Understanding Geological Structures

The first step in any underground drilling operation is understanding the geological structures beneath the surface. Geologists utilize a variety of techniques, including seismic surveys, core sampling, and geological mapping, to gather data about subsurface formations. This information is crucial for identifying potential drilling sites and assessing the viability of resource extraction.

The Role of Engineering in Underground Drilling

Engineering plays a pivotal role in the design and execution of underground drilling projects. Engineers must overcome numerous challenges, including varying rock formations, high temperatures, and extreme pressure conditions. They employ cutting-edge technologies such as directional drilling, hydraulic fracturing, and tunnel boring machines to navigate through the Earth’s crust with precision and efficiency.

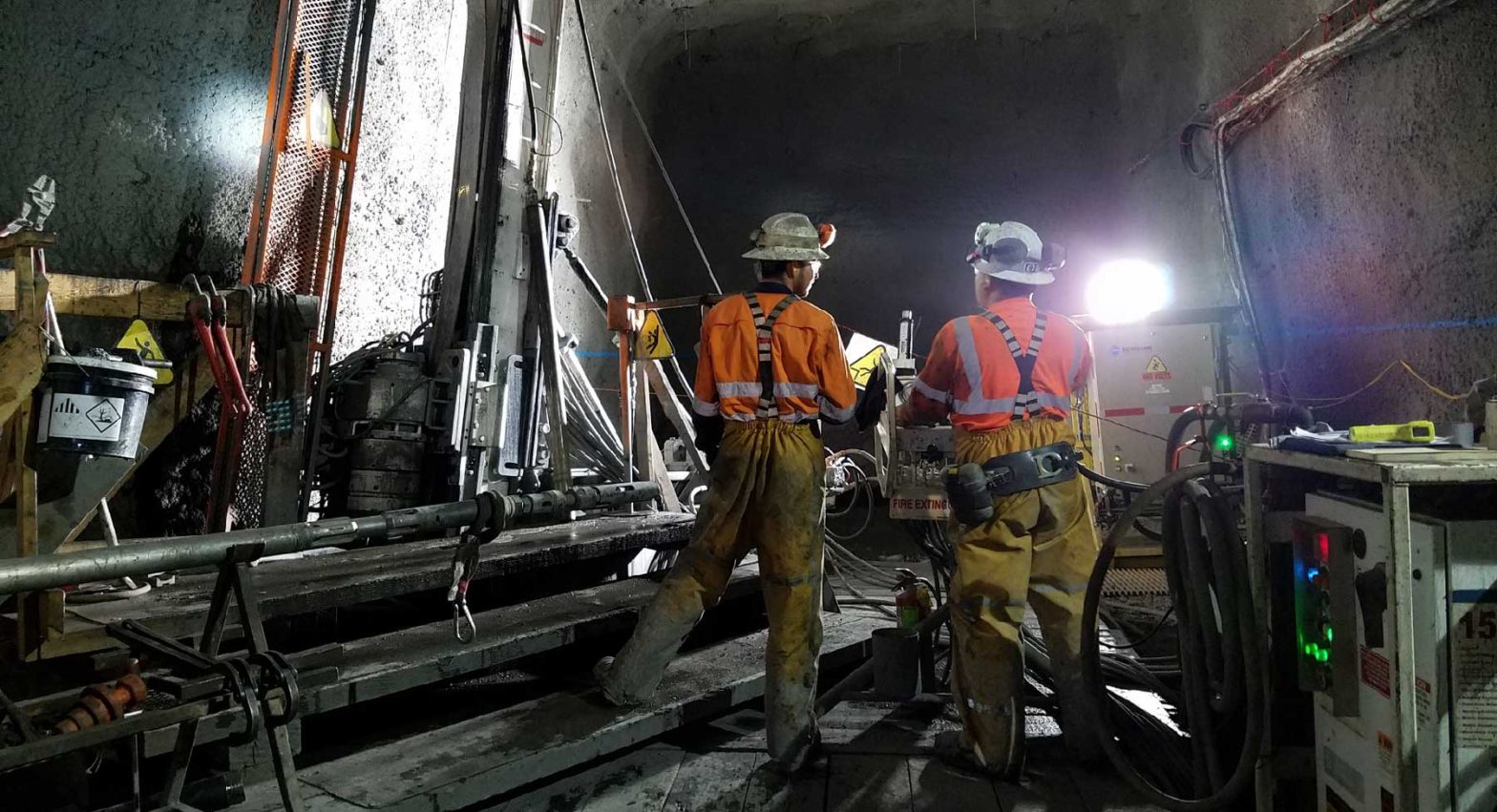

The Mechanics of Underground Drilling

Underground drilling involves a complex interplay of mechanical, hydraulic, and thermal processes. Drill rigs equipped with powerful rotary drills and diamond-tipped bits penetrate the Earth’s crust, creating boreholes that extend deep into the ground. Hydraulic systems facilitate the circulation of drilling fluids, which serve multiple purposes, including cooling the drill bit, removing rock cuttings, and stabilizing the borehole walls.

Advancements in Drill Bit Technology

One of the most critical components of any drilling operation is the drill bit. Over the years, significant advancements have been made in drill bit technology to enhance performance and durability. Tungsten carbide inserts, diamond coatings, and optimized cutting geometries enable drill bits to penetrate even the toughest rock formations with ease, increasing drilling efficiency and reducing downtime.

Managing Downhole Conditions

As drilling depths increase, so do the challenges posed by downhole conditions. Extreme temperatures, high pressures, and corrosive environments can wreak havoc on drilling equipment. Engineers employ sophisticated techniques such as mud logging, well logging, and downhole instrumentation to monitor and mitigate these challenges in real-time, ensuring the safety and effectiveness of the drilling operation.

Environmental Considerations

In an era of increasing environmental awareness, underground drilling operations must adhere to stringent regulations to minimize their ecological footprint. Techniques such as directional drilling and horizontal drilling allow for resource extraction with minimal surface disruption and habitat disturbance. Additionally, the proper management and disposal of drilling waste and chemicals are essential to prevent contamination of soil and groundwater resources.

Exploring Sustainable Energy Sources

The shift towards sustainable energy sources has spurred interest in underground drilling for geothermal energy, carbon capture and storage, and enhanced geothermal systems. These technologies leverage the Earth’s natural heat and geological formations to generate clean energy while reducing greenhouse gas emissions. By harnessing the power of underground resources, we can mitigate climate change and secure a more sustainable future for generations to come.

Minimizing Environmental Impact

Efforts to minimize the environmental impact of underground drilling extend beyond energy production. In mining operations, strategies such as backfilling, reclamation, and mine closure planning are employed to restore disturbed land and ecosystems. By prioritizing environmental stewardship and sustainable practices, we can strike a balance between resource extraction and conservation, ensuring the long-term health of our planet.

The Future of Underground Drilling

As technology continues to advance, the future of underground drilling holds immense promise. From autonomous drilling rigs to advanced materials and sensing technologies, innovation will drive efficiency, safety, and sustainability in subterranean exploration and resource extraction. By embracing the principles of science and engineering, we can unlock the full potential of the Earth’s vast underground frontier while safeguarding its ecosystems for future generations. https://drillitco.com.au/directional-drilling-queensland/