Different Types of Directional Drills – A Comprehensive Guide

Directional drilling, also known as horizontal directional drilling (HDD), is a method used to install underground utilities, pipelines, and conduits without the need for traditional open trenching. This technique has revolutionized the construction industry by minimizing disruption to the environment and infrastructure. Let’s explore the various types of directional drills used in different applications.

1. Conventional Directional Drills

Conventional directional drills are the most common type of HDD equipment. They consist of a drill pipe, a drilling fluid system, and a powerful drill rig. The drill bit is advanced through the soil or rock, creating a pilot bore. Once the pilot bore is completed, the hole is enlarged using a series of reamers to accommodate the desired utility or pipeline size.

Advantages:

- Cost-effective for shorter bores.

- Suitable for a wide range of soil conditions.

- Can install multiple utilities in a single bore.

Limitations:

- Challenging in hard rock formations.

- May require additional time for reaming.

2. Mini Directional Drills

Mini directional drills, also known as compact drills, are designed for smaller-scale projects and residential areas. They are more maneuverable and compact compared to conventional drills, making them ideal for tight spaces and urban environments. Mini drills are commonly used for installing fiber optic cables, water lines, and electrical conduits.

Advantages:

- Minimal surface disruption, suitable for urban areas.

- Lower operational costs for smaller projects.

- Can navigate through narrow access points.

Limitations:

- Limited bore length and diameter capabilities.

- May struggle with challenging soil conditions.

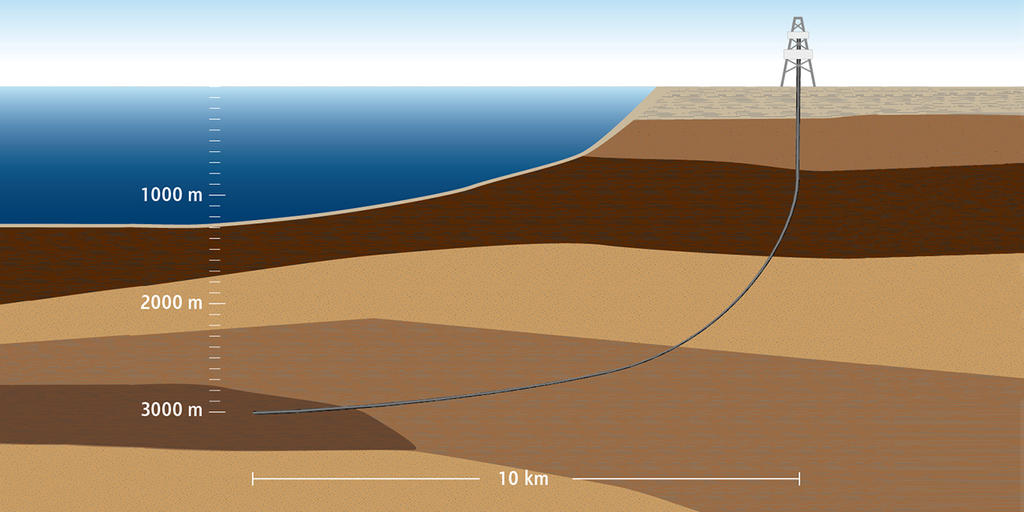

3. Extended Reach Directional Drills

Extended reach directional drills are designed to tackle long-distance bores, often exceeding 2,000 feet. These drills are commonly used for river crossings, highway bores, and other projects where a straight-line installation is essential. They require specialized equipment and expertise due to the complexities of maintaining accuracy over such extended distances.

Advantages:

- Capable of covering significant distances.

- Reduces the need for multiple entry and exit points.

- Suitable for environmentally sensitive areas.

Limitations:

- Higher costs due to specialized equipment and training.

- Requires precise planning and surveying.

4. Steerable System Directional Drills

Steerable system directional drills utilize advanced technology to control the direction of the drill head in real-time. This allows operators to make adjustments during drilling, ensuring accurate alignment and reducing the risk of errors. These drills are commonly used in projects that demand a high degree of precision.

Advantages:

- Exceptional accuracy and control.

- Reduced risk of bore deviations.

- Efficient in complex projects.

Limitations:

- Higher upfront investment.

- Requires skilled operators.

5. Walk-Beside Directional Drills

Walk-beside directional drills, also known as pedestrian rigs, are compact drills that can be operated by a single person. These drills are suitable for smaller installations and are often used in areas where larger equipment cannot access easily. Walk-beside drills are commonly employed for short bores in landscapes, gardens, and environmentally sensitive regions. For types of directional drills on the gold coast read here.

Advantages:

- Minimal surface disruption.

- Operable in tight spaces.

- Easy transportation to job sites.

Limitations:

- Limited bore length and diameter capabilities.

- Not suitable for larger projects.

In conclusion, directional drills come in various types, each catering to specific project requirements. Whether it’s a conventional drill for general applications, an extended-reach drill for long bores, or a steerable system for precision projects, the choice depends on factors such as project size, soil conditions, and desired accuracy. By selecting the right type of directional drill, construction professionals can ensure efficient installations with minimal disruption.