Maximum Depth of Directional Drilling: Exploring Depths in Drilling Technology

Directional drilling, a remarkable feat of modern engineering, has revolutionized the oil and gas industry by allowing access to hydrocarbon reserves that were once unreachable using traditional vertical drilling techniques. This technique involves drilling non-vertical wells to reach reservoirs beneath the Earth’s surface. One crucial aspect that often arises is the maximum depth achievable through directional drilling.

Understanding Directional Drilling

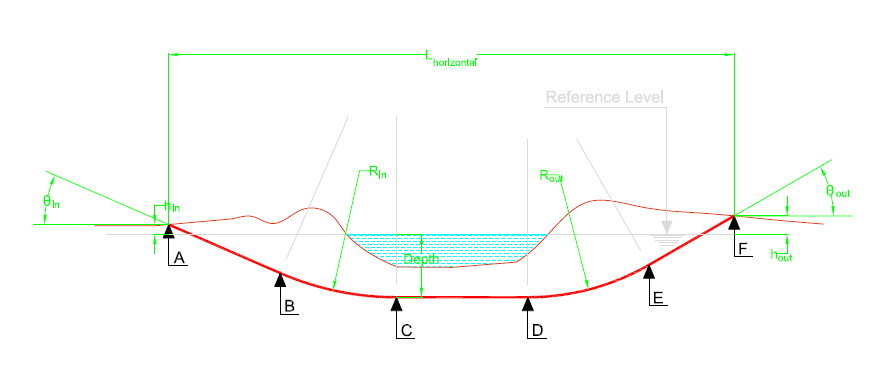

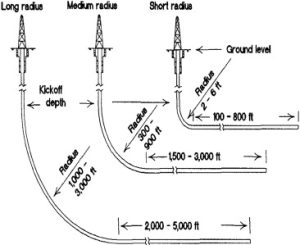

Directional drilling involves deliberately deviating from the vertical path, enabling access to reserves that lie horizontally beneath the surface. This technique is employed when reservoirs are situated under urban areas, water bodies, or environmentally sensitive regions where traditional drilling is impractical or prohibited. The process employs sophisticated tools, including mud motors, measurement while drilling (MWD) systems, and rotary steerable systems, to control the well’s trajectory.

The Factors Influencing Maximum Depth

Several factors impact the maximum depth achievable through directional drilling:

- Geological Composition: The type of rock formations and their hardness play a significant role. Softer formations might limit drilling depth due to stability issues, while harder formations can challenge tool wear and tear.

- Drilling Equipment: The quality and capabilities of drilling equipment directly affect how deep a well can be drilled. Advanced equipment can withstand greater pressures and temperatures at depth.

- Technological Advancements: As drilling technology advances, tools become more durable and efficient, allowing for deeper drilling. Innovations like improved cutters and stronger materials enhance drilling performance.

- Wellbore Stability: Maintaining the stability of the wellbore is crucial to prevent collapse or deviations. This becomes more challenging at greater depths due to higher pressure and temperature differentials.

- Formation Fluids and Pressure: The pressure and type of fluids present in the rock formations affect drilling. High-pressure reservoirs can limit the depth due to the risk of blowouts or well control issues.

The Ongoing Quest for Record Depths

Over the years, drilling companies and engineers have continuously pushed the boundaries of directional drilling depths. Technological breakthroughs have enabled drilling at record depths that were once considered unattainable. As of my last update in September 2021, the deepest directional well reached around 40,320 feet in the Marcellus Shale, a significant milestone in the industry. Find more here.

The Future of Directional Drilling Depths

The pursuit of even greater depths in directional drilling continues. As technology evolves, drilling companies are investing in research and development to create tools and techniques capable of withstanding extreme conditions. The development of novel materials, advanced cooling systems, and real-time data analytics will likely play a pivotal role in achieving unprecedented depths.

In conclusion, the maximum depth achievable through directional drilling is influenced by geological factors, equipment quality, technological advancements, wellbore stability, and reservoir conditions. While record depths have been reached, the industry’s relentless pursuit of innovation suggests that even greater depths will be achieved in the future. As technology marches forward, the depths we can explore beneath the Earth’s surface are poised to expand, opening new frontiers for resource extraction and scientific discovery.

Note: For the most current information beyond September 2021, please refer to updated industry sources.