What is the Core Drilling Process?

When it comes to extracting cylindrical samples from concrete, rock, or other hard materials, core drilling is the go-to method. This process is widely used in construction, geology, and various industries where precision drilling and sample collection are essential. In this article, we’ll delve into the core drilling process, its applications, and the equipment involved.

Understanding Core Drilling

What is Core Drilling?

Core drilling, also known as diamond core drilling or concrete core drilling, is a specialized technique used to create perfectly round holes in hard materials. Unlike traditional drilling methods that rely on rotating metal bits, core drilling employs a diamond-tipped core bit to cut through the material. The result is a clean, cylindrical core sample that can provide valuable insights into the composition and quality of the material being drilled.

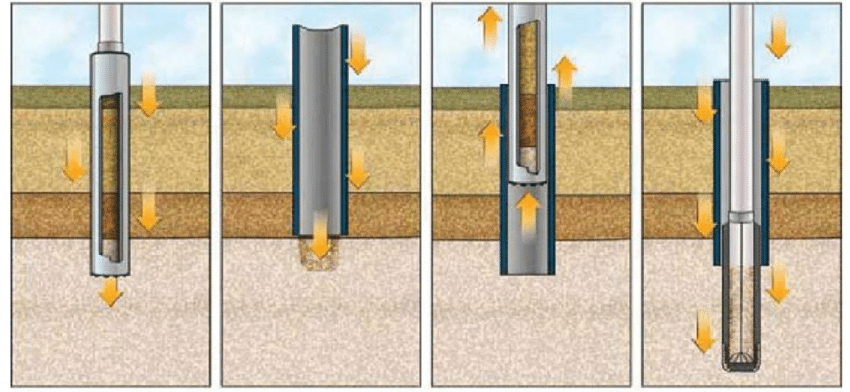

How Does Core Drilling Work?

The core drilling process involves several key components and steps:

1. Core Bit Selection:

Selecting the right core bit is crucial to the success of the drilling operation. Core bits come in various sizes and types, each designed for specific materials. Diamond-tipped core bits are the most commonly used due to their exceptional cutting efficiency and durability.

2. Drill Rig Setup:

A drill rig is used to stabilize and guide the core drilling process. It consists of a motor, a column, and an adjustable base. The drill rig holds the core bit securely in place and ensures precise drilling.

3. Coolant System:

Core drilling generates a significant amount of heat, which can damage the core bit and reduce drilling efficiency. A coolant system is used to lubricate the core bit and keep it cool during the drilling process. Water is commonly used as a coolant.

4. Drilling Process:

With the core bit in place and the coolant system activated, the drilling process begins. The operator guides the core bit into the material, applying steady pressure. As the diamond-tipped core bit rotates, it cuts through the material, creating a cylindrical core sample.

5. Core Retrieval:

Once the drilling is complete, the core sample is carefully extracted from the hole. This cylindrical sample can be analyzed for various purposes, including material composition, quality assessment, and structural integrity.

Applications of Core Drilling

Core drilling finds extensive applications across different industries:

Construction and Engineering

In construction and engineering, core drilling is used to create holes for utility installations, such as plumbing, electrical, and HVAC systems. It is also essential for obtaining samples from concrete structures to assess their strength and quality. Find out what core drilling is here.

Geological Exploration

In geology, core drilling plays a vital role in exploring the Earth’s subsurface. Geologists use core samples to study rock formations, assess mineral deposits, and understand the Earth’s geological history.

Environmental Monitoring

Core drilling is used in environmental science to collect soil and sediment samples for pollution analysis and groundwater monitoring. These samples help scientists understand the impact of human activity on the environment.

Materials Testing

Core drilling is crucial for testing the quality and integrity of materials such as asphalt, metal, and ceramics. It allows manufacturers to ensure their products meet the required specifications and standards.

Benefits of Core Drilling

Core drilling offers several advantages:

1. Precision:

Core drilling produces accurate, circular holes with minimal deviation, making it ideal for applications where precision is essential.

2. Sample Collection:

It provides intact core samples that are representative of the material, allowing for detailed analysis.

3. Minimal Dust and Debris:

Unlike traditional drilling methods, core drilling generates less dust and debris, reducing cleanup efforts.

4. Versatility:

Core drilling can be used on a wide range of materials, including concrete, rock, metal, and more.

5. Efficiency:

Diamond-tipped core bits are highly efficient and long-lasting, reducing downtime and maintenance costs.

Conclusion

In summary, core drilling is a versatile and precise method used for creating holes and collecting cylindrical core samples in hard materials. Its applications span various industries, from construction and engineering to geology and environmental science. Understanding the core drilling process and its benefits is crucial for professionals seeking reliable and accurate drilling solutions in their respective fields. Whether you need to install utilities, explore the Earth’s subsurface, or assess material quality, core drilling is a valuable tool that delivers results with precision and efficiency.