Understanding Pipe Lining Thickness

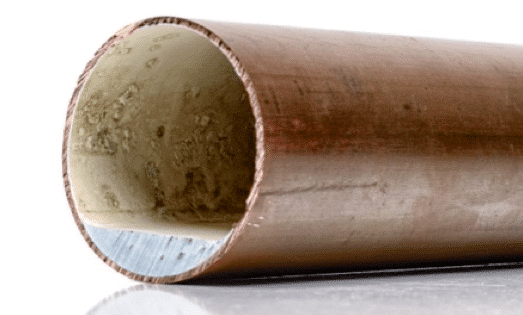

Introduction: Pipe lining is a crucial aspect of modern plumbing and infrastructure maintenance. It involves placing a protective layer inside pipes to enhance durability and extend their lifespan. One of the key considerations in this process is the thickness of the lining, as it directly influences the effectiveness and longevity of the solution. How thick is pipe lining?

Factors Influencing Pipe Lining Thickness

Pipe lining thickness is determined by various factors, each playing a significant role in ensuring the optimal performance of the lining. These factors include:

- Pipe Material: Different pipe materials may require different lining thicknesses. The compatibility between the lining material and the pipe material is crucial for longevity.

- Application: The purpose of the pipe also affects the required thickness. For example, pipes used for transporting corrosive substances may need a thicker lining for added protection.

- Environmental Conditions: The surrounding environment, including temperature, humidity, and exposure to external elements, can impact the required thickness of the pipe lining.

Standard Thickness Ranges

Pipe lining thickness is not a one-size-fits-all solution, and it often varies based on industry standards and specific project requirements. However, there are general thickness ranges that are commonly observed in pipe lining applications:

- Thin-Layer Lining: Ranging from 2 to 5 millimeters, thin-layer linings are suitable for less severe conditions where the primary goal is to prevent corrosion and enhance flow.

- Moderate Thickness: Typically between 5 and 12 millimeters, moderate thickness linings offer enhanced protection and are suitable for a wide range of applications, including industrial pipelines.

- Heavy-Duty Lining: For extreme conditions and high-stress environments, heavy-duty linings with thicknesses exceeding 12 millimeters may be required to provide maximum protection and durability.

Benefits of Optimal Pipe Lining Thickness

Maintaining the correct thickness in pipe lining offers several benefits to the overall functionality and longevity of the piping system:

- Corrosion Resistance: Adequate thickness acts as a barrier, protecting the pipe from corrosive substances and preventing deterioration over time.

- Structural Integrity: Proper lining thickness ensures the structural integrity of the pipe, reducing the risk of cracks, leaks, and other damages.

- Extended Lifespan: Pipes with optimal lining thickness tend to have a longer lifespan, reducing the frequency of replacements and maintenance.

Conclusion

In conclusion, understanding the thickness of pipe lining is crucial for ensuring the longevity and performance of piping systems. By considering factors such as pipe material, application, and environmental conditions, industry professionals can determine the appropriate thickness range for their specific needs. Adhering to optimal thickness standards provides enhanced corrosion resistance, structural integrity, and an extended overall lifespan for pipes. https://drillitco.com.au/directional-drilling-gold-coast/